Turbo Generator Division

With the world-renowned expertise of Tadeusz Sarzynski, a recognized leader in generator design, troubleshooting, and maintenance, we specialize in turbogenerators, hydro generators, and all types of large synchronous electrical rotating machines. We provide inspection, testing, and project management support services.

Our Services

Our specialized Turbo-Generator Division (TGD) is committed to ensuring the reliability, safety, and operational integrity of your generator assets throughout their lifecycle.

We offer comprehensive testing and inspection services that are designed to meet and exceed insurance and regulatory expectations while minimizing operational risks.

Through our engagement, we can help minimize maintenance costs, and help prolong the lifespan of your power production assets.

Click on our listed services below to learn more.

-

Our comprehensive diagnostic tests assess the overall electrical health of your generator, including insulation resistance, polarization index, and winding copper resistance tests.

Benefit: Regular diagnostic testing ensures that any electrical issues are detected early, allowing for timely maintenance and avoiding unexpected generator failures.

-

We develop customized maintenance Inspection Test Plans (ITPs) tailored to the specific needs of your turbines and generators.

These plans are designed to cover the entire lifecycle of your equipment, ensuring that all critical inspections and tests are performed at the right intervals to maintain operational integrity, extend equipment life, reduce downtime, and ensure compliance with industry standards.

Benefit: By implementing a well-structured maintenance ITP, you can proactively prevent unexpected failures, reduce repair costs, maintain continuous operation, and extend the life of your assets. This approach ensures that all necessary inspections and tests are conducted, helping to avoid costly downtime and improve the reliability of your power generation equipment.

-

Our project management services ensure that your maintenance, inspection, and testing projects are executed efficiently and on schedule. We oversee every aspect, from planning and scheduling to execution and post-project analysis.

Benefit: Effective project management minimizes disruptions and ensures that all activities are aligned with your operational goals, leading to smoother and more predictable outcomes.

-

We conduct thorough risk analysis surveys to identify potential hazards and vulnerabilities in your turbine and generator operations.

Benefit: Understanding and mitigating risks leads to safer operations, protecting both your assets and personnel.

-

Our advisory services provide you with expert guidance on all aspects of turbogenerator management, from maintenance strategies, to troubleshooting, to long-term asset planning.

Benefit: Leveraging our expertise helps you make informed decisions that enhance the reliability and efficiency of your power generation assets.

Generator Diagnostic Electrical Tests

Our comprehensive diagnostic tests assess the overall electrical health of your generator, including insulation resistance, polarization index, and winding copper resistance tests.

Click the services listed below for more information.

-

We offer both permanent and temporary installations of air-gap flux probes to monitor the magnetic flux in your generator’s air gap. This is crucial for detecting rotor field issues early, and once installed, we are able to provide a comprehensive examination of shorted turns in your rotor while varying load conditions during normal operation.

Benefit: Early detection of rotor field issues helps prevent catastrophic failures and extends the life of your generator, reducing the likelihood of costly repairs.

-

We conduct off-line RSO tests to identify shorted turns in the generator rotor field. This method is effective in diagnosing issues in case the generator is at a standstill either before or after outages, after shipping, and before installation into the generator, or if the generator is incapable of operating for any unknown reason and needs to investigate the reasons for being incapacitated.

Benefit: Off-line RSO testing provides a deeper analysis of rotor integrity, allowing for precise maintenance actions and avoiding further damage.

-

EL-CID testing is used to identify imperfections in the generator's electromagnetic core, which can lead to inefficiencies and potential failures.

Benefit: Detecting and addressing core imperfections early can prevent energy losses and extend the operational life of your generator.

-

We install PD monitoring devices to detect and monitor partial discharges within the insulation of your generator. This service includes both online and offline PD testing and analysis.

Benefit: Continuous PD monitoring allows for the early detection of insulation degradation, helping to avoid insulation failures and ensuring long-term reliability.

-

Using the TVA probe, we can pinpoint areas of partial discharge activities within the stator slot sections otherwise not visible. We provide an exact mapping of the entire stator indicating the levels of damage.

Benefit: TVA slot scanning is a specific technique used within the broader context of PD testing or other diagnostic methods, often targeting particular areas of concern identified by initial PD testing.

At Systems Approach West, our Turbogenerator division, in partnership with Generatortech Inc., is at the forefront of shorted turn detection and analysis for power generators. We provide comprehensive solutions that include the design, installation, and analysis of air gap flux probes, a critical tool in maintaining the operational integrity of your generators.

Air-Gap Flux Probe Installation and Testing

What is Air Gap Flux Probe Testing?

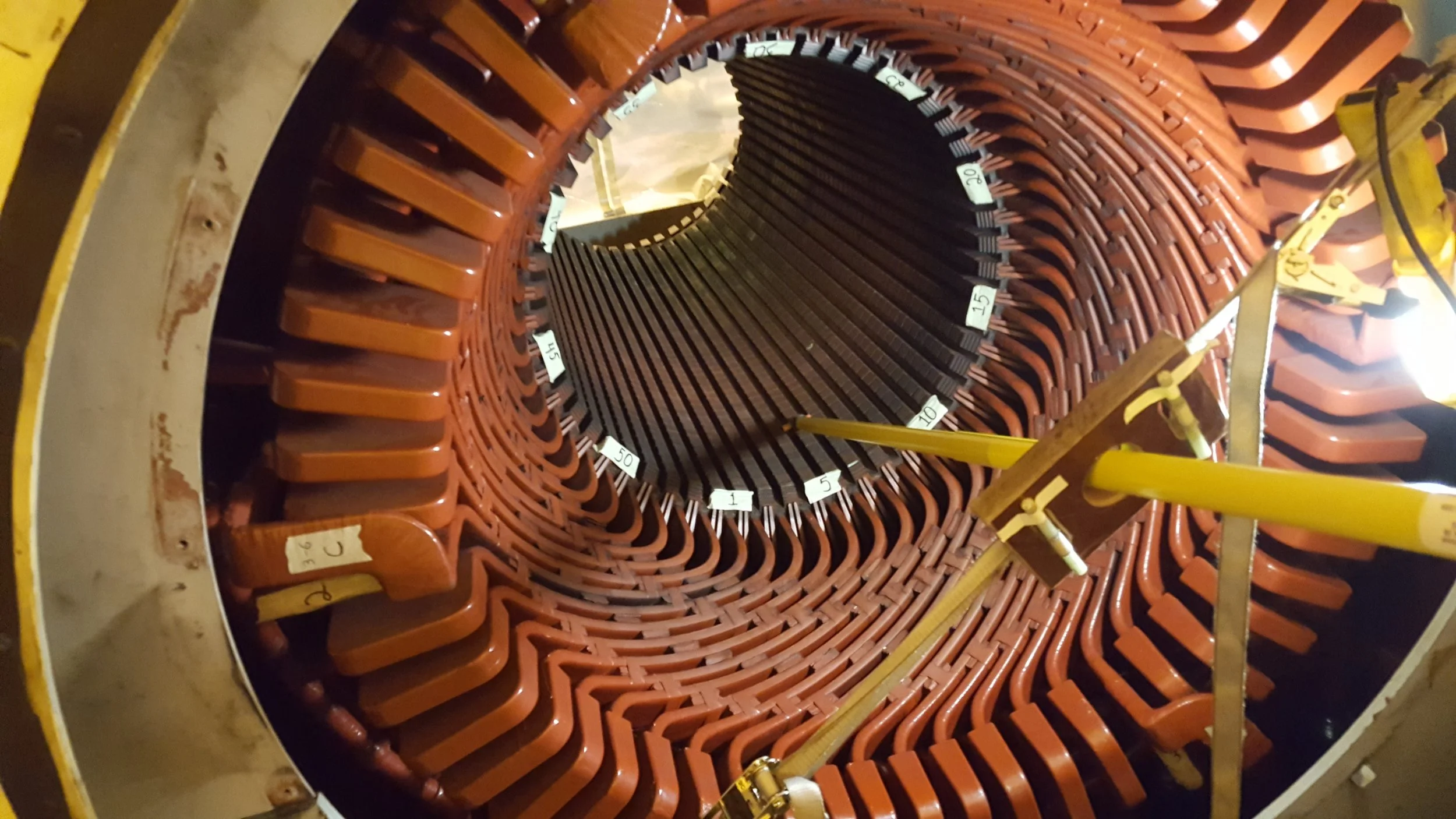

Air gap flux probe testing is an advanced method used to detect shorted turns in generator rotor windings. Shorted turns occur when the insulation between individual windings fails, leading to several operational issues, such as:

Load-Sensitive Vibration: This can lead to mechanical stress and potential damage to the generator over time.

Undetected Local Winding Hot Spots: These hot spots can degrade insulation further and lead to catastrophic failures if not identified early.

Excessive Excitation Currents: This increases the operational cost and reduces the efficiency of the generator.

Efficiency Losses: Overall, the presence of shorted turns decreases the efficiency of the generator, leading to higher operational costs and potential downtime.

The flux probe works by measuring changes in the magnetic flux density within the stator-rotor air gap. These changes are recorded at various load conditions and analyzed to detect the presence and extent of shorted turns. By comparing the flux density at each rotor slot with its opposing pole slot, our system can accurately determine the number of inactive or "shorted" turns.

Why Air Gap Flux Probe Testing is Valuable

In today’s competitive electrical power market, predictive maintenance is essential for minimizing maintenance costs and avoiding unexpected downtime. Regular monitoring of your rotor windings using air gap flux probes allows for:

Proactive Maintenance Decisions: Determine the optimal time for maintenance activities such as rotor rewinds, avoiding unnecessary downtime.

Verification of Rotor Integrity: After a rotor rewind, flux probe testing verifies the quality of the work performed, ensuring that the generator is operating at peak efficiency.

Enhanced Reliability: Regular testing helps identify potential issues before they lead to failure, improving the overall reliability of your power generation assets.

When conducting air gap flux probe testing, varying the load on the generator is crucial for obtaining accurate and comprehensive data on the condition of the rotor windings. The primary reason for this is that different loads on the generator produce varying levels of magnetic flux within the air gap, which in turn can affect the detection of shorted turns.

Importance of Varying Load During Flux Probe Testing

Why Does Varying the Generator Load Matter?

Enhanced Detection Sensitivity: Shorted turns may only manifest under certain load conditions. By varying the load, we can observe how the magnetic flux density changes across different operating scenarios. This variation helps in identifying shorted turns that might not be apparent under a constant load.

Comprehensive Analysis: Varying the load allows for a more complete analysis of the rotor windings. Different loads can induce different stress levels on the insulation, potentially revealing weaknesses that would go unnoticed if the generator were tested under a single, constant load.

Accurate Diagnosis: The relationship between load and magnetic flux is not linear, meaning that the effects of shorted turns can become more pronounced or less detectable depending on the load. Testing under various loads ensures that we capture the full spectrum of the rotor’s behavior, leading to a more accurate diagnosis.

Testing Under Constant Load:

Limitations: Conducting the test under a constant load can limit the ability to detect all shorted turns. Since certain shorted turns may only become evident at specific load conditions, a constant load might miss these issues, resulting in an incomplete assessment of the rotor’s condition.

Risk of Misdiagnosis: Without load variation, the test may not reveal all the potential issues within the rotor windings, leading to a false sense of security or an inaccurate diagnosis of the generator’s health.

Which is Better?

Varying the Load: Varying the load during air gap flux probe testing is the preferred method because it provides a more accurate and comprehensive assessment of the rotor windings. This approach maximizes the detection of shorted turns and ensures that any potential issues are identified across a range of operating conditions. While testing under a constant load can provide some information, varying the load is significantly more effective. It offers a deeper and more reliable understanding of the rotor’s condition, ultimately leading to better maintenance decisions and improved generator reliability.

Our Services

Air Gap Flux Probe – Permanent Installation: We design and install permanent air gap flux probes tailored to your generator’s specific needs. Our technicians mount a durable search coil on a stator slot wedge, with cabling routed through a hydrogen gas-tight seal to an external connection fixture. The flux probe, cabling and installation materials are resistant to the harsh environment within the generator. This permanent setup allows for continuous monitoring without interfering with rotor installation or removal.

Air Gap Flux Probe - Temporary Installation: For short-term monitoring needs, we offer temporary flux probe installation, providing flexibility and cost-effective testing without the need for permanent modifications.

Online Testing and Analysis: We conduct online flux probe testing under various load conditions to monitor the condition of rotor windings in real time. The data collected provides a detailed snapshot of the winding’s insulation condition, enabling early detection of shorted turns. Our analysis software, developed with plant maintenance staff in mind, is user-friendly and operates on MS-Windows, requiring minimal training. The software allows for easy data acquisition and analysis, making it accessible for on-site personnel.

Comprehensive Reporting and Trend Analysis: Our TurboGenerator Division (TGD) provides detailed reports following each test, including trend analysis based on historical data. This approach helps in tracking the progression of winding conditions over time and in making informed maintenance decisions.

Baseline and Periodic Testing: We recommend establishing a baseline for new or rewound rotors and conducting periodic testing as part of a predictive maintenance strategy. This testing is typically performed before and after major outages, and semi-annually, depending on generator availability and operational demands.

Benefits of Our Air Gap Flux Probe Services

Precision in Operational Efficiency: Partnering with Generatortech Inc., the pioneers in shorted turn analysis, Systems Approach West offers industry-leading expertise to identify issues before they escalate. By detecting shorted turns early, we help you maintain optimal generator efficiency and prevent unnecessary energy losses, ensuring your operations run smoothly.

Targeted Maintenance for Cost Savings: Our advanced detection methods enable targeted maintenance, allowing you to address specific issues rather than undertaking costly, broad-spectrum repairs. This focused approach reduces downtime and overall maintenance costs, keeping your generator operating efficiently.

Maximized Equipment Longevity: Through regular testing and analysis, we help extend the lifespan of your generators. By catching and addressing potential problems early, our services prevent further damage and ensure your equipment remains reliable over time.

Strict Compliance with Industry Standards: We ensure that your generator operates safely within its design parameters, meeting all industry standards and regulatory requirements. Our services not only enhance safety but also ensure that your equipment is always in compliance, reducing the risk of costly penalties or shutdowns.

Why Choose Us?

Our collaboration with Generatortech Inc. provides unmatched expertise and capability in generator inspection and maintenance, making us the trusted choice for ensuring the longevity and reliability of your power generation assets.

Generator Rotor Repetitive Surge Oscilloscope (RSO) Test and Analysis

Overview

The Repetitive Surge Oscilloscope (RSO) test is a critical offline diagnostic tool designed to detect shorted turns in generator rotor windings. These shorted turns can lead to several operational issues, such as increased vibration due to rotor thermal bending, unbalanced magnetic flux in the air gap, and higher excitation demands, which can reduce the efficiency and reliability of the generator.

How it Works

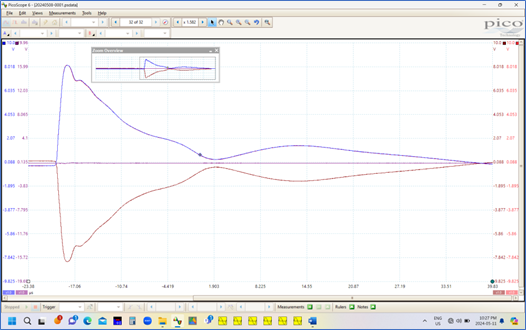

RSO testing involves injecting two identical "twin" signals from opposite ends of the generator rotor windings. An oscilloscope captures the signals and any reflections that occur. The test is based on Time Domain Reflectometry, which uses the principle that a signal encountering a change in wave impedance - like that caused by a shorted turn - will result in a reduced through signal and a reflected signal.

The symmetry of the rotor winding ensures that in the absence of faults, the through and reflected signals will be almost identical. However, the presence of a shorted turn creates a discontinuity in the wave impedance, causing variations in the reflected signals. RSO testing detects these variations, allowing for the precise identification of shorted turns.

Our RSO Testing Services

Shorted Turn Detection: Our RSO testing services are focused on detecting shorted turns in the rotor windings. By identifying these issues early, we help prevent further damage and costly repairs.

Detailed Analysis and Reporting: We provide comprehensive analysis and detailed reports, highlighting any issues detected during the RSO test. Our reports include actionable insights that allow for informed maintenance decisions.

Customized Maintenance Planning: Based on the RSO test results, we assist in developing a tailored maintenance plan that addresses the specific needs of your generator. This ensures that potential issues are managed before they escalate, reducing the risk of unplanned outages.

Collaboration with Generatortech Inc.: In partnership with Generatortech Inc., industry pioneers in generator diagnostics, we offer state-of-the-art RSO testing services. Our collaboration ensures that you receive the highest quality of service, backed by the latest technology and industry expertise.

Benefits of RSO

Accurate Diagnostics: RSO testing provides precise information on the rotor’s condition, enabling early detection of shorted turns that might not be identified through other methods.

Cost-Effective Maintenance: By pinpointing issues early, RSO testing helps in planning targeted maintenance activities, reducing the likelihood of extensive repairs and minimizing downtime.

Enhanced Generator Longevity: Regular RSO testing as part of a structured maintenance plan helps extend the operational life of your generator, ensuring it continues to operate efficiently and reliably.

Why Choose Us?

Our RSO testing services are designed to keep your power generation assets operating at peak performance. With our expertise and partnership with Generatortech Inc., we deliver reliable, high-quality diagnostics that help you maintain the integrity and efficiency of your equipment. Whether you’re planning routine maintenance or addressing specific operational concerns, our RSO testing services provide the detailed insights needed to make informed decisions and ensure the long-term reliability of your generators.

Electromagnetic Core Imperfection Detection (EL-CID) Testing

Overview

Electromagnetic Core Imperfection Detection (EL-CID) is an advanced diagnostic test used to identify imperfections in the electromagnetic core of a generator. These imperfections, if left unaddressed, can lead to inefficiencies, potential failures, and costly repairs. EL-CID testing is particularly valuable because it allows for the early detection of core issues without requiring the generator to be fully operational, providing a crucial insight into the health of the generator's core.

How it Works

PHASE Signal: This part of the signal is in phase with the reference signal and is primarily due to the magnetic flux resulting from the core excitation. The PHASE signal is relatively large and is present throughout the core, regardless of the presence of faults.

QUADRATURE Signal: This component, detected at a phase angle of 90° from the excitation field, is induced by fault currents in the core. The QUADRATURE signal is critical for identifying imperfections in the core, as it indicates the presence of induced fault currents.

EL-CID testing involves scanning the core surface of the generator longitudinally along the stator winding slots. During the test, an operator uses a Chattock potentiometer placed at the outer edges of two adjacent slots to detect any potential imperfections. The EL-CID system measures two main components of the signal:

The EL-CID system processes these signals using a reference input from the excitation current, separating them into their respective PHASE and QUADRATURE components. The processed signals are then recorded to create a series of traces, which display the sensor position along the bore (x-axis) and the amplitude of any fault currents (y-axis). These traces allow for detailed analysis and identification of core imperfections.

Our EL-CID Test Services

Core Imperfection Detection: We conduct EL-CID testing to detect imperfections in the electromagnetic core of your generator. This sensitive test, which requires the removal of the rotor from the generator, can identify even minor damage that may affect the generator's efficiency and reliability.

Detailed Analysis and Reporting: Our team provides a comprehensive analysis of the EL-CID test results, offering detailed reports that include traces of the fault currents and their corresponding locations. This allows for informed decision-making regarding any necessary repairs or maintenance.

Calibration and Customization: The EL-CID system is calibrated before each test to provide accurate readings of fault current values. We adjust the test parameters based on the specific generator's excitation level to ensure the most accurate and relevant results.

Collaboration with Industry Leaders: In partnership with leading industry experts, we deliver EL-CID testing services using state-of-the-art technology and proven methodologies. This ensures that you receive the highest quality service and reliable results.

Benefits of EL-CID

Early Detection of Core Imperfections: EL-CID testing identifies core imperfections early, allowing for timely repairs and preventing more serious issues from developing.

Reduced Downtime: By detecting potential core issues during planned maintenance outages, EL-CID testing helps avoid unplanned outages and reduces the overall downtime of your generator.

Enhanced Generator Longevity: Regular EL-CID testing as part of your maintenance plan helps extend the operational life of your generator by addressing core imperfections before they lead to significant damage.

Improved Operational Efficiency: Identifying and repairing core imperfections ensures that your generator operates at peak efficiency, reducing energy losses and optimizing performance.

Why Choose Us?

Our EL-CID testing services are designed to provide you with detailed insights into the condition of your generator's electromagnetic core. With our advanced testing techniques, expert analysis, and collaboration with industry leaders, we ensure that your generators operate reliably and efficiently. Whether you’re conducting routine maintenance or addressing specific concerns, our EL-CID testing services offer the critical information needed to maintain the integrity and performance of your power generation assets.

Partial Discharge (PD) Monitoring & Device Installation

Overview

Partial Discharge (PD) testing is a critical diagnostic tool used to assess the condition of the insulation in generator stator windings. PD testing can be performed both online (while the generator is operational) and offline (with the generator de-energized). These tests are essential for identifying insulation degradation early, allowing for timely maintenance and preventing costly failures. Systems Approach West offers comprehensive PD testing services, including the installation of PD monitoring devices, analysis, and reporting, to ensure the long-term reliability and efficiency of your power generation equipment.

How it Works

Online PD Testing: Online PD testing is conducted while the generator is operational, offering real-time insights into the insulation condition under normal load conditions. This test focuses on the highest voltage sections of the stator windings, where insulation stress is most likely to occur. Online PD testing is less invasive than offline testing and can be performed without taking the generator offline, making it an excellent tool for monitoring and early detection of insulation issues.

Ongoing Monitoring: Online PD testing provides continuous data on the insulation's condition, allowing operators to detect and respond to emerging issues promptly. This proactive approach helps in preventing unplanned outages and extending the operational life of the generator.

Offline PD Testing: Offline PD testing involves energizing each phase of the generator stator windings individually, while the other two phases are shorted and grounded. This testing method directly energizes the stator windings at both ends, typically resulting in higher Partial Discharge (PD) levels compared to online testing. The test is designed to provide a detailed analysis of the insulation condition across the entire winding, including areas not exposed to high voltage during normal operation. The offline PD test is particularly valuable for trending purposes, helping to monitor insulation health over time.

Phase Plots and Classic PD: During offline testing, phase plots reveal the relationship between the PD pulse and the phase-to-ground reference voltage. This data helps identify the origin of PD within the slot portion of the coil. Classic PD, usually occurring in the slot section, is a key indicator of insulation stress in these areas. The test results are analyzed in 3D snapshots, providing a comprehensive view of PD activities across almost all winding regions. It’s important to note that offline PD test results should be used for trending rather than condemning the insulation, as they are more sensitive and cover areas typically not exposed to high voltage.

Our PD Test Services

Installation of PD Monitoring Devices: We install advanced PD monitoring devices on your generator, capable of both online and offline testing. These devices are designed to provide accurate and reliable data, essential for assessing the health of the insulation over time.

Online PD Testing and Continuous Monitoring: We perform online PD testing to monitor the insulation condition during normal operation. This service includes the continuous analysis of PD activity, enabling timely interventions before significant insulation failures occur.

Offline PD Testing and Analysis: Our technicians conduct offline PD tests using state-of-the-art equipment to energize and measure each phase of the stator windings. The results are carefully analyzed to identify any potential insulation degradation, with detailed reports provided to guide maintenance decisions.

Data Analysis and Trending: We offer comprehensive data analysis services, comparing PD test results over time to identify trends in insulation degradation. This trending analysis is crucial for making informed decisions about maintenance schedules and potential rewinding needs.

Benefits of PD Testing

Improved Generator Reliability: Early detection of insulation degradation through PD testing helps prevent unexpected failures, ensuring continuous and reliable generator operation.

Cost-Effective Maintenance: By identifying insulation issues early, our PD testing services enable targeted maintenance, reducing the need for extensive repairs and minimizing downtime.

Extended Equipment Lifespan: Regular PD testing and monitoring help extend the operational life of your generator by preventing the progression of insulation damage.

Compliance with Industry Standards: Our PD testing services ensure that your generator meets industry requirements and operates safely within its design parameters.

Why Choose Us?

At Systems Approach West, we provide comprehensive PD testing services that are essential for maintaining the health and reliability of your generators. With industry-leading expertise and cutting-edge technology, we offer both online and offline PD testing solutions tailored to your specific needs. Our services are designed to protect your assets, optimize performance, and ensure long-term operational success.

Time-Varying Voltage Analysis (TVA) Stator Slot Scanning

Overview

TVA (Time-Varying Voltage Analysis) Slot Scanning is a specialized diagnostic technique used to assess the condition of the insulation in the stator slots of rotating electrical machines, such as generators and motors. This method focuses on detecting insulation defects, mechanical issues, and partial discharge activity within the slots, which are critical areas prone to insulation stress.

Systems Approach West offers comprehensive TVA Slot Scanning services to help you identify and address potential issues early, ensuring the long-term reliability and performance of your power generation equipment.

How it Works

TVA Slot Scanning: TVA Slot Scanning involves applying a time-varying voltage across the stator slots while scanning each slot to detect any partial discharges or anomalies. This process is performed while the machine is offline and the field (rotor) is removed, allowing for a detailed inspection of the insulation condition within the slots. By focusing on the slot area, TVA Slot Scanning can identify specific problems such as loose windings, insulation degradation, and other mechanical issues that might not be detected by broader testing methods.

Targeted Analysis: The TVA method provides precise information about the condition of insulation within each stator slot. By detecting partial discharges and other electrical activities, this technique helps pinpoint the exact location of defects, allowing for targeted maintenance and repair efforts. The high sensitivity of TVA Slot Scanning makes it particularly effective for identifying early-stage insulation issues that could lead to more severe problems if left unaddressed.

Detailed Reporting: After scanning, the data is analyzed to produce a comprehensive report highlighting any detected issues and their severity. This report is invaluable for maintenance planning, enabling you to address specific concerns before they escalate into major failures.

Our TVA Services

Comprehensive Slot Scanning: We perform detailed slot-by-slot scanning of your stator windings, using advanced TVA technology to detect even the smallest signs of insulation degradation or mechanical issues. Our thorough approach ensures that all potential problem areas are identified and documented.

Data Analysis and Diagnostics: Our team of experts analyzes the scanning data to diagnose the condition of your stator insulation. We provide detailed insights into the specific issues found, along with recommendations for corrective actions.

Maintenance Planning: Based on the findings from the TVA Slot Scanning, we help you develop a targeted maintenance plan to address identified issues. This proactive approach minimizes the risk of unexpected failures and extends the operational life of your equipment.

Customized Reporting: We deliver a detailed report that includes a summary of the findings, visual representations of the scanned data, and actionable recommendations. This report serves as a valuable tool for guiding maintenance decisions and ensuring the ongoing reliability of your machine.

Benefits of TVA Inspection

Early Detection of Issues: TVA Slot Scanning allows for the early identification of insulation and mechanical problems within stator slots, preventing costly failures and extending the life of your equipment.

Targeted Maintenance: By pinpointing specific issues, our TVA Slot Scanning services enable you to focus your maintenance efforts where they are most needed, reducing downtime and repair costs.

Enhanced Equipment Reliability: Regular slot scanning helps maintain the integrity of your stator insulation, ensuring consistent and reliable operation of your generators and motors.

Informed Decision-Making: The detailed insights provided by our TVA Slot Scanning reports give you the information needed to make informed decisions about maintenance and repair strategies.

Why Choose Us?

At Systems Approach West, we provide comprehensive PD testing services that are essential for maintaining the health and reliability of your generators. With industry-leading expertise and cutting-edge technology, we offer both online and offline PD testing solutions tailored to your specific needs. Our services are designed to protect your assets, optimize performance, and ensure long-term operational success.

Maintenance Inspection & Test Plans

We understand the critical importance of ensuring that large synchronous power generators operate reliably and efficiently throughout their lifecycle. To meet this need, we help our clients to develop customized maintenance plans that include comprehensive annual online, offline, and major inspection and test schedules tailored to your specific equipment.

Our maintenance plans are designed to encompass the full spectrum of generator operational needs, ensuring timely intervention and thorough inspection at key intervals. This approach helps in maintaining operational integrity, extending equipment life, and ensuring compliance with both industry standards and insurance provider expectations.

We offer comprehensive support in all three aspects of generator monitoring and maintenance planning.

Proactive Issue Resolution: Our maintenance plans integrate annual online and offline diagnostic tools, including advanced tests such as Air-Gap Flux Probe testing, Partial Discharge (PD) testing (both online and offline), Recurrent Surge Oscillograph (RSO) testing, Doble Tip-Up testing, and Electromagnetic Core Imperfection Detection (EL-CID). Additionally, we perform bump testing of stator end windings to assess resonance and stability. Coupled with detailed visual and borescope inspections, this comprehensive approach allows for the proactive identification and resolution of potential issues, significantly reducing the risk of unplanned outages and extending the generator’s service life.

Extended Equipment Life: Through regular and meticulous inspections, including both minor outages and major overhauls, we ensure that your generator operates at peak efficiency. This not only maximizes the return on your investment but also reduces long-term operational costs by preventing premature equipment failures.

Compliance with Insurance and Regulatory Requirements: Our maintenance schedules are designed to exceed industry standards and align with the directives and expectations of insurance providers and regulatory bodies. This ensures your operations remain fully compliant with all relevant safety, environmental, and insurance requirements, thereby protecting your assets and minimizing operational risks.

Benefits of a Structured Maintenance Plan

Our Services

-

Online Testing and Diagnostics:

We conduct periodic online tests, including Air Gap Flux Probe testing and Partial Discharge (PD) testing, on an annual or semi-annual basis depending on the service, age, condition, and duty of the unit. These tests are critical for detecting rotor field shorted turns and other potential issues while the generator is in operation.

Benefit: Regular online testing allows for the early detection of deviations from normal operating conditions, enabling prompt corrective actions. This proactive approach minimizes the risk of unexpected failures, ensuring the generator's reliability and operational continuity.

-

Offline Diagnostic Tests:

During planned maintenance outages, we conduct a range of offline tests, including Repetitive Surge Oscilloscope (RSO) testing, Doble Tip-Up testing, Partial Discharge (PD) testing, and insulation resistance measurements. These tests provide a comprehensive assessment of the generator's internal condition, particularly focusing on the insulation integrity and identifying any latent issues.

Visual and Borescope Inspections: In conjunction with offline electrical tests, we perform thorough visual and borescope inspections of the generator’s critical components, including the rotor, stator, iron core, and excitation systems. These inspections allow us to detect signs of wear, contamination, and mechanical damage that may not be evident through electrical testing alone.

Benefit: Offline testing combined with detailed visual and borescope inspections ensures a holistic assessment of the generator’s health. This comprehensive approach enables the identification of both electrical and mechanical issues, leading to more accurate diagnostics and targeted maintenance actions.

-

Periodic Major Inspections: We assist in scheduling and planning major inspections at intervals recommended by the manufacturer, requested by the insurance provider, or based on the generator’s operational history, typically every 5-7 years. By incorporating the results of our annual online and offline tests, we prioritize key initiatives to ensure the ongoing integrity and reliability of your generators. These inspections are crucial for maintaining the long-term performance of the generator and involve a complete disassembly of the unit. Key activities include:

Rotor Removal and Testing: During major outages where a rotor removal is required, we can conduct Electromagnetic Core Imperfection Detection (EL-CID) testing, which identifies any potential issues with the stator core’s insulation and magnetic properties.

Bump Tests: We perform bump tests on the end windings to assess resonance frequencies and evaluate blocking stability. This ensures that the windings are secure and stable during operation, reducing the risk of mechanical failure due to resonance.

Visual and Mechanical Inspections: A thorough visual inspection of all generator components, including the stator, rotor, and excitation system, is conducted to identify any signs of wear, damage, or contamination. Additionally, bearing inspections are performed to assess the condition of these critical components and plan for any necessary maintenance or replacements.

Benefit: Major inspections are essential for ensuring the long-term reliability and safety of your generator. By identifying and addressing potential issues through these comprehensive overhauls, we help extend the operational life of your generator and prevent catastrophic failures. The detailed testing and inspections we perform during these major overhauls ensure that all components are functioning correctly and that any issues are resolved before they can lead to significant problems.

We provide our clients with a full spectrum of testing, monitoring, and inspection plans designed to ensure the reliability and efficiency of your power generation equipment. Our offerings include both online and offline diagnostic testing, as well as comprehensive planning and coordination for major shutdown inspections.

Why Choose Us?

By implementing a well-structured maintenance plan through Systems Approach West’s Turbo-Generator division, you can effectively prevent unexpected failures, reduce repair costs, and ensure the continuous, reliable operation of your power generation assets.

Project Management

Our project management services are designed to deliver meticulous oversight and execution for all generator maintenance, inspection, and refurbishment projects. When acting as an owner site-rep, we ensure that every phase is handled with the highest level of expertise, ensuring efficiency, reliability, and adherence to industry standards. Our key services include stator rewind management, rotor refurbishment oversight, and major inspection coordination which includes owner site-rep supervisory capabilities.

-

We manage the entire process of stator bar procurement, replacement, and installation.

Our team collaborates directly with OEMs and trusted suppliers to source high-quality stator bars.

When outsourcing competitive bids for non-OEM replacements, we can provide reverse engineering services to ensure precision replacements can be fabricated by competitors.

We oversee the logistics of endurance testing and transportation, while working closely with your operations team to minimize disruptions.

During installation, we ensure that each bar is fitted according to precise OEM specifications, using state-of-the-art tools and techniques to achieve optimal performance.

-

We provide comprehensive owner site-rep oversight of rotor refurbishment activities, including but not limited to shipping , dismantling, cleaning, painting, block replacement, and insulation replacement.

Our project managers coordinate with vendors to inspect the rotor and identify components requiring repair.

We then work to verify every aspect of the refurbishment plan, ensuring that the replacement of worn or damaged components are correctly executed, unnecessary work is avoided, and all activities are completed meticulously.

We ensure that all off-site work to your rotor is completed to the highest standards, with rigorous quality checks at each stage.

-

We coordinate and manage major generator inspections, ensuring thorough assessments and effective repairs.

Our process begins by defining the schedule parameters within planned outage windows to minimize operational impact.

We then provide specialized reviews of previous inspection and test reports, operating performance data, insurance requirements, and regulatory guidelines to help define the outage scope.

Relying on a risk-based approach to prioritizing work tasks, we work with our clients to establish all activities to work within the available outage schedule.

We rely on cutting edge technologies to complete our inspections of the stator, rotor, and other critical components.

After the inspection, we oversee any necessary repairs or adjustments while acting as the owner’s site-rep during reassembly and testing to ensure that your generator is ready for reliable operation.

Our Execution Strategy

Detailed Project Planning: We develop a comprehensive project plan outlining each step, from procurement and scheduling to execution and final testing. This plan is created in collaboration with your team to align with your operational timelines, budget, and expectations.

Expert Team Coordination: Our project managers ensure seamless communication and execution by coordinating between engineers, technicians, suppliers, and your in-house staff. We are able to manage the workflow, assign responsibilities, and track progress to keep your projects on schedule.

Quality Assurance: We implement strict quality control measures throughout the project. Regular inspections, testing, and validation at each critical stage ensure that all work meets industry standards and the specific requirements of your equipment and organization.

Risk Management: We proactively identify potential risks to the project timeline or quality and implement mitigation strategies to prevent issues before they arise. This keeps the project on track and within budget.

Post-Project Analysis: After the project is completed, we conduct a thorough analysis to evaluate the success of the project, document lessons learned, and provide detailed reports on the outcomes. This information is invaluable for planning future maintenance and improvements.

Why Choose Us?

By leveraging our comprehensive project management services, you can ensure that your generator maintenance, inspection, and refurbishment projects are executed with precision and efficiency. Our approach minimizes downtime, optimizes resource use, and enhances the reliability and performance of your power generation assets.

Risk Analysis Surveys

Risk Analysis Surveys are a critical component of ensuring the safety and reliability of turbine and generator operations.

These surveys involve a comprehensive assessment of potential hazards and vulnerabilities within your operational environment.

By identifying and evaluating risks, Systems Approach West helps you implement effective mitigation strategies, enhancing both safety and operational efficiency.

Our Strategy

-

Our process begins with a thorough data collection phase, where we gather all relevant information about your turbine and generator systems.

This includes reviewing historical performance data, P&ID’s, control / loop narratives, maintenance records, operational procedures, and any previous incident reports.

We then conduct a detailed site assessment to observe the physical condition of the equipment, operational practices, and environmental factors that could contribute to risk.

-

During the site assessment, we identify potential hazards associated with your turbine and generator operations.

These could include mechanical failures, electrical issues, environmental conditions, human factors, and operational inefficiencies.

We utilize industry-standard methodologies, such as Failure Modes and Effects Analysis (FMEA) and Process Hazard Analysis (PHA), to systematically identify and document these hazards.

Through our relationship with the PHA specialists at LupaTech Ltd. Canada, we offer a unique and hands-on approach to a PHA through the proprietary MI-HAZOP method - a hazard and operability study which combines a detailed examination of the mechanical integrity of equipment and systems.

-

Once hazards are identified, we evaluate the likelihood and potential impact of each risk.

This involves using quantitative and qualitative risk assessment techniques to prioritize risks based on their severity and probability.

We also consider factors such as operational redundancy, existing safety measures, and the potential consequences of risk realization.

-

After assessing the risks, we develop tailored mitigation strategies designed to reduce or eliminate identified hazards.

These strategies may include engineering controls, procedural changes, enhanced monitoring, and targeted maintenance activities.

We work closely with your team to ensure that these strategies are practical, effective, and aligned with your operational goals.

-

Following the risk analysis survey, we provide a comprehensive report detailing our findings and recommendations.

This report includes a prioritized list of risks, suggested mitigation measures, and a timeline for implementation.

Our recommendations are designed to enhance the safety and reliability of your turbine and generator operations, minimizing the potential for unplanned outages and catastrophic failures.

Our Risk Analysis Services:

Site Assessment and Hazard Identification: Our team conducts detailed site assessments to identify potential hazards within your turbine and generator systems. We use industry-standard tools and methodologies to ensure that all risks are thoroughly documented and understood.

Risk Evaluation and Prioritization: We evaluate the identified risks based on their likelihood and potential impact, prioritizing them according to their severity. This allows you to focus your resources on the most critical risks, ensuring that your mitigation efforts are both effective and efficient.

Development of Mitigation Strategies: We work with your team to develop practical and effective mitigation strategies tailored to your specific operational needs. These strategies are designed to reduce or eliminate risks, enhancing the safety and reliability of your equipment.

Comprehensive Reporting: Our risk analysis surveys culminate in a detailed report that outlines our findings, risk evaluations, and recommended mitigation measures. This report serves as a roadmap for improving the safety and reliability of your turbine and generator operations.

Benefits:

Enhanced Safety: By identifying and mitigating potential hazards, our risk analysis surveys help ensure the safety of your personnel and equipment, reducing the likelihood of accidents and incidents.

Increased Operational Efficiency: Proactively addressing risks leads to more reliable operations, minimizing downtime and optimizing performance.

Cost Savings: Early identification and mitigation of risks can prevent costly repairs and unplanned outages, protecting your investment and extending the life of your equipment.

Regulatory Compliance: Our risk analysis surveys help you meet industry regulations and standards, ensuring that your operations are fully compliant and minimizing the risk of legal or financial penalties.

Why Choose Us?

We are committed to helping you safeguard your assets and personnel through comprehensive risk analysis surveys. Our expert team combines industry knowledge with cutting-edge methodologies to deliver actionable insights that enhance safety, reliability, and efficiency. By partnering with us, you gain the peace of mind that comes with knowing your operations are protected from potential risks.

Advisory & Supervisory Support Services

Systems Approach West offers comprehensive Advisory and Supervisory Services to support all aspects of your turbogenerator management. Whether you need expert guidance on maintenance strategies, assistance with troubleshooting, or supervision during critical operations, our team is here to provide the specialized knowledge and experience you need to optimize the performance and reliability of your power generation assets.

Our Advisory and Supervisory Services Include:

-

We work closely with your team to develop customized maintenance strategies that are tailored to the specific needs of your turbogenerators.

By analyzing operational data, equipment history, and industry best practices, we help you implement maintenance programs that prevent unexpected failures, extend equipment life, and reduce downtime.

Our advisory services ensure that your maintenance plans are not only effective but also aligned with your long-term operational goals.Description text goes here

-

Our supervisory services provide you with on-site expertise during critical maintenance, inspection, and repair activities.

Whether you're conducting a major overhaul, installing new equipment, or performing routine maintenance, our experienced professionals oversee the work to ensure it is executed according to the highest standards of quality and safety.

We also provide hands-on troubleshooting assistance, helping to quickly diagnose and resolve any issues that arise during operations.

-

When unexpected issues occur, our troubleshooting services are designed to provide swift and effective solutions.

We leverage our deep understanding of turbogenerator systems to diagnose problems accurately and recommend corrective actions that minimize disruption and restore normal operations as quickly as possible.

Our experts are equipped to handle a wide range of technical challenges, from mechanical failures to electrical malfunctions.

-

Our advisory services extend beyond immediate concerns to include long-term asset planning.

We help you develop strategies for the ongoing management of your turbogenerators, focusing on maximizing their operational lifespan and optimizing performance.

This includes advising on equipment upgrades, lifecycle management, and the integration of new technologies to keep your power generation assets at peak efficiency.

-

We ensure that your operations adhere to all relevant regulatory requirements and industry standards.

Our advisory services include guidance on compliance issues, helping you navigate complex regulations and implement practices that meet or exceed industry expectations.

This not only protects your operations from legal or financial penalties but also enhances the overall safety and reliability of your power generation assets.

Benefits:

The benefits of our advisory and / or supervisory involvement include :

Informed Decision-Making: Our expert guidance empowers you to make informed decisions that enhance the reliability and efficiency of your turbogenerators.

Minimized Downtime: With our supervisory and troubleshooting services, you can quickly address and resolve issues, minimizing disruptions to your operations.

Optimized Asset Performance: Through long-term planning and strategic maintenance, we help you optimize the performance and lifespan of your power generation assets.

Regulatory Assurance: Our services ensure that your operations remain compliant with all relevant regulations, reducing the risk of penalties and enhancing operational safety.

Peace of Mind: By partnering with Systems Approach West, you gain access to the expertise and support you need to manage your turbogenerators with confidence.

Why Choose Us?

At Systems Approach West, our goal is to provide you with the expert support and guidance needed to manage your turbogenerators effectively. With years of industry experience and a commitment to excellence, our team is dedicated to helping you achieve the highest levels of operational reliability, safety, and efficiency.

Whether you need assistance with maintenance planning, troubleshooting, or long-term asset management, our advisory and supervisory services are designed to meet your needs and exceed your expectations.