Introducing SYSTEM, a comprehensive asset lifecycle management program

From initial design support to end-of-life planning, SYSTEM integrates strategic risk management, advanced inspection methodologies, and proactive maintenance strategies to maximize asset value, enhance safety, and maintain operational continuity.

At Systems Approach West, we believe that effective asset management requires a holistic approach that integrates safety and reliability into every stage of the asset lifecycle. Our unique offering, SYSTEM - Strategic Yield and Safety Through Engineering Mastery - is designed to provide organizations with the tools and expertise needed to ensure their assets operate safely and efficiently from the design phase through to decommissioning.

SYSTEM is more than just a management tool; it's a philosophy that places Safety-by-Design at the forefront of asset management. We work closely with asset owners to embed safety considerations into the design and operational phases, helping to mitigate risks before they materialize.

Safety-by-Design: The Heart of SYSTEM

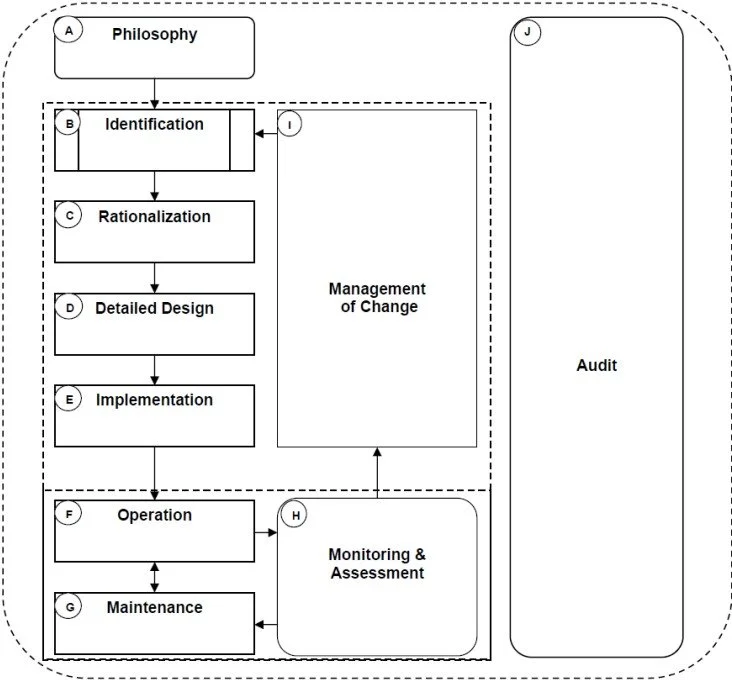

Safety-by-Design is our commitment to ensuring that safety is an integral part of every decision made throughout the asset lifecycle. By proactively addressing safety and reliability from the outset, we help organizations avoid costly downtime, enhance operational reliability, and ensure compliance with industry standards. Our SYSTEM comprises of 10 elements, developed to help industrial organizations reach their peak operational excellence.

SYSTEM is a comprehensive asset management program designed to maximize safety, reliability, and operational efficiency throughout the entire lifecycle of your assets. Our approach is built on 10 key elements, each addressing critical aspects of asset management. These elements work together to provide a holistic and proactive strategy, ensuring that your assets are managed with precision and foresight.

Explore each element below to discover how SYSTEM can enhance your operations.

The SYSTEM Approach: Key Components

-

Begin your project with confidence by ensuring that safety and reliability are integrated from the very start. Our approach to scoping and design prioritizes operational goals while embedding critical safety considerations, resulting in assets that are not only efficient but also resilient and compliant. Explore how we can set your project up for success with our detailed scoping and design strategies.

-

Ensure your designs meet the highest standards of safety, reliability, and efficiency with our thorough design reviews. We meticulously evaluate every aspect of your project, from regulatory compliance to industry best practices, to optimize performance and prevent costly errors. Discover how our design reviews can enhance the success and longevity of your assets.

-

Mitigate risks and enhance safety with our expert coordination of Process Hazard Analysis (PHA) and Failure Modes and Effects Analysis (FMEA). We partner with industry leaders to identify potential hazards and failure points, ensuring your operations are secure and efficient from the outset. Learn how our coordinated approach can safeguard your processes and optimize performance.

-

Optimize your asset performance and minimize downtime with our strategic maintenance planning services. We combine preventive and predictive maintenance techniques to create customized plans that address your specific operational needs. Discover how our tailored approach can extend the life of your assets and ensure continuous, reliable operation.

-

Safeguard your assets by maintaining them within safe operating limits with our Integrity Operating Window (IOW) management services. We establish and monitor critical parameters, in line with API RP 584, ensuring your equipment operates within designed thresholds to prevent damage and extend lifespan. Learn how our IOW management, grounded in industry standards, can protect your assets and enhance operational reliability.

-

Protect your assets from one of the most common and costly forms of degradation with our Corrosion Circuit Development services. Corrosion circuits are defined pathways that trace the flow of corrosive agents through your equipment, allowing for targeted monitoring and maintenance. We develop customized corrosion circuits based on API 571 standards, ensuring that potential corrosion is detected early and managed effectively. Explore how our approach can help extend the life of your equipment and maintain its operational integrity.

-

Ensure your operations meet or exceed industry regulations with our comprehensive compliance inspection services. We develop inspection programs tailored to your specific needs, aligning with API 510, 570, 653, and API 576 standards for pressure vessels, piping, and pressure relief devices such as PSV's and rupture discs. By staying ahead of regulatory requirements, we help you maintain safety, avoid penalties, and ensure the continuous reliability of your assets.

-

Apply the proven principles of Risk-Based Inspection (RBI) across all industries with our tailored RBI methodologies. By systematically assessing the risk of failure in your assets, we prioritize inspections where they matter most, ensuring safety and reliability. Our approach, grounded in API RP 580/581 standards, is adaptable to any industry, helping you optimize resources and enhance operational performance. Discover how we bring the power of RBI to your organization, regardless of the sector.

-

Enhance your operational safety and efficiency by optimizing your alarm systems with our Alarm Rationalization & Management services. We systematically evaluate and refine alarm settings to ensure each alert is meaningful and prioritized based on risk. By eliminating unnecessary alarms and focusing on critical notifications, we empower your operators to respond swiftly and accurately, reducing stress and improving overall system reliability. Discover how our expert management of alarm systems can streamline your operations and safeguard your assets.

-

Maximize the lifespan and reliability of your assets with our dynamic approach to continuous improvement. From detailed life assessments and strategic decision-making to ongoing SYSTEM audits and regulatory or industry updates, we ensure your operations stay ahead of the curve. Discover how our tailored strategies can keep your assets performing at their best, while adapting to industry changes and ensuring long-term success.

Supporting Safe and Reliable Scoping and Design

-

We work directly with you to understand your operational objectives and constraints. By aligning the design with your specific goals, we ensure that the project is tailored to meet your needs while adhering to the highest standards of safety and reliability.

-

From the outset, we focus on integrating safety and reliability into every aspect of the design. Our expertise in applying relevant standards ensures that critical safety considerations are not just added on as afterthoughts but are embedded into the design process, reducing the risk of costly modifications or safety issues down the line.

-

In addition to safety and reliability, we place a strong emphasis on operability and maintainability. By considering how the asset will be used and maintained by personnel over its lifecycle, we help ensure that the designs are operator friendly, and supports efficient, cost-effective maintenance practices that keep the asset operating smoothly with minimal downtime.

-

Our involvement in the scoping and design phase is comprehensive, covering all aspects from materials selection to system layout and operational workflows. We consider not only the immediate needs but also the long-term operational and maintenance requirements, ensuring that your asset is both robust and adaptable to future challenges.

-

We ensure that the design is fully aligned with relevant regulatory requirements and industry best practices. This not only safeguards compliance but also positions your project for long-term success by adhering to proven, effective design principles.

We believe that the foundation of a successful project lies in the careful and strategic scoping and design phase. Our approach is centered on close collaboration with asset owners to define clear operational goals and ensure that safety, reliability, operability, and maintainability are prioritized from the very beginning.

Expand each consideration below for more information.

By engaging Systems Approach West early in the scoping and design process, you benefit from a partnership that prioritizes safety, reliability, and maintainability. Our approach ensures that your assets are not only designed to perform but are also built to last.

Comprehensive Design Reviews

Our design reviews are meticulously crafted to ensure that every aspect of your project meets the highest standards of safety, reliability, and operational efficiency. We leverage our extensive industry experience to evaluate designs against a wide array of critical criteria, ensuring that your assets are set up for long-term success.

Expand each consideration below for more information.

-

Our foremost priority is to ensure that your designs meet all safety and operational requirements. We conduct thorough evaluations to identify potential risks and implement measures to mitigate them, ensuring that your assets are not only compliant but also resilient against potential hazards.

-

Navigating the complex landscape of industry regulations is crucial for the successful operation of any asset. Our team ensures that your designs are fully compliant with relevant local, national, and international regulations, helping you avoid costly delays and legal challenges.

-

We bring a wealth of knowledge in industry standards and best practices to our design reviews. By benchmarking your designs against API, ASME, ANSI, and ISO standards, we help ensure that your assets are built to the latest and most robust specifications.

-

In addition to regulatory and industry considerations, we also review designs to meet the specific requirements of insurance providers. This ensures that your assets are not only safe and compliant but also eligible for the most favorable insurance terms, protecting your investment over the long term.

-

Our design reviews are comprehensive, taking into account all aspects of the project, from materials and construction methods to long-term maintenance and operational needs. This holistic approach ensures that every design is thoroughly vetted and optimized for both current and future conditions.

-

At Systems Approach West, we understand the importance of having a Professional Engineer (P.Eng.) endorse your designs to meet regulatory and industry standards. Our P.Eng. endorsement services include a detailed review of your engineering drawings and documentation to ensure that they meet the necessary criteria for safety, reliability, and compliance.

By providing a P.Eng. stamp and signature on your designs, we not only validate the technical integrity of your project but also offer you the assurance that your designs have been rigorously evaluated by qualified professionals. This endorsement is critical for projects requiring regulatory approval, insurance underwriting, and adherence to legal obligations.

Our P.Eng. services extend beyond mere validation; we collaborate closely with your engineering team to refine designs where necessary, ensuring that the final product not only meets but exceeds industry standards. Whether for a small pump skid or a complex system, our endorsements contribute to the overall credibility and acceptance of your project, safeguarding your investment and supporting the long-term success of your assets.

By integrating these critical factors into our design reviews, Systems Approach West ensures that your projects are not only compliant with all necessary standards but are also optimized for safety, reliability, and long-term operational success.

PHA & FMEA Coordination

Through a long relationship with German Luna Meijas, a leader in Process Safety, we have partnered with LupaTech Ltd. to bring top-tier Process Safety Management expertise to our Process Hazard Analysis (PHA) and Failure Mode Effect Analysis (FMEA) services.

With LupaTech Ltd.’s extensive experience in the Oil, Gas, Pulp & Paper, Smelting / Refining, and Petrochemical industries, we ensure that safety is embedded in every phase of your asset lifecycle.

Together we offer the following:

-

Identifying and mitigating potential hazards with industry-leading insights. We conduct HAZID's, Checklists, What-If's, and HAZOP's, including the implementation of LupaTech’s proprietary MI-HAZOP method for integrating mechanical integrity into hazard and operability studies.

Click HERE to learn more about LupaTech Ltd. Canada's additional industry-leading PHA services.

-

Systematically assessing and addressing potential failure modes. Once the FMEA process narrows down potential failures to manageable root causes, we assist in developing Preventive Maintenance (PM), Predictive Maintenance (PdM), and Operator-Driven Reliability (ODR) strategies. These proactive measures help monitor for early indicators of failure, enhancing asset reliability from the outset. Through hands-on guidance, we empower your team to maintain operational uptime and take control of the equipment's long-term performance.

-

We offer tailored Process Safety Management (PSM) solutions that are specifically designed to integrate seamlessly with your operations. Our approach begins with a thorough assessment of your current safety processes and identifies areas for improvement. We then develop customized strategies that align with industry standards and best practices, ensuring that safety is deeply embedded in every aspect of your operation.

From initial consulting to full implementation, we work closely with your team to create a robust PSM framework that enhances safety, reduces risk, and supports continuous operational excellence.

Our collaboration with LupaTech Ltd. ensures that your assets are managed with the highest safety standards, leveraging combined experience and commitment to quality and safety.

Preventative and Predictive Maintenance Planning

At Systems Approach West, we understand that effective maintenance planning is key to preventing asset failures and extending the operational life of your equipment. Our approach is centered on collaboration with your maintenance and operating personnel - the experts closest to the equipment - ensuring that maintenance strategies are not only effective but also practical and aligned with your operational realities.

Expand each consideration below for more information.

-

We work closely with your maintenance team to develop customized maintenance plans that address the specific needs of your assets. By tapping into the knowledge and experience of your personnel, we ensure that our strategies are grounded in real-world understanding and tailored to the unique demands of your operation.

-

Our maintenance plans combine the best of preventative and predictive maintenance strategies. Preventative maintenance focuses on scheduled inspections and servicing to prevent failures, while predictive maintenance leverages data and condition monitoring to anticipate issues before they occur. In both cases, we help organizations optimize the PM and PdM programs. This dual approach helps improve asset performance and extends operational life.

-

We assist in rationalizing your spare parts inventory, ensuring that you have the right parts on hand when needed while minimizing excess stock. This not only reduces inventory costs but also improves efficiency by ensuring that critical components are readily available to prevent extended downtime.

-

Our maintenance planning services are designed to minimize unplanned downtime by identifying potential issues early and addressing them proactively. By optimizing maintenance schedules and integrating predictive techniques, we help keep your assets running smoothly and efficiently, maximizing their availability and productivity.

-

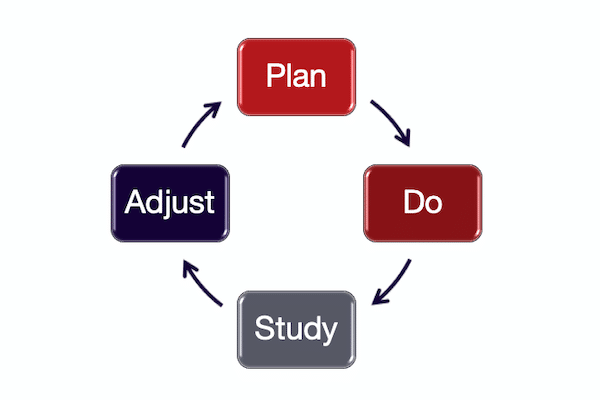

Maintenance planning is not a one-time task - it requires ongoing evaluation and adjustment. We provide audit services to routinely monitor the effectiveness of your maintenance strategies and make adjustments as needed to respond to changing conditions, ensuring that your maintenance practices remain effective over the long term.

By partnering with Systems Approach West for maintenance planning, you gain access to a collaborative and comprehensive approach that enhances asset reliability, optimizes performance, and reduces costs.

Integrity Operating Window (IOW) Management

We recognize the critical importance of maintaining your assets within safe operating limits. By working with us to identify Integrity Operating Windows (IOW), you can rest assured that your assets operate safely within defined parameters, minimizing the risk of degradation and extending their operational life. By integrating IOW’s into daily operations, IOW excursions can be tracked, with the impact to assets being evaluated, and inspection regimens adjusted accordingly.

Expand each consideration below for more information.

-

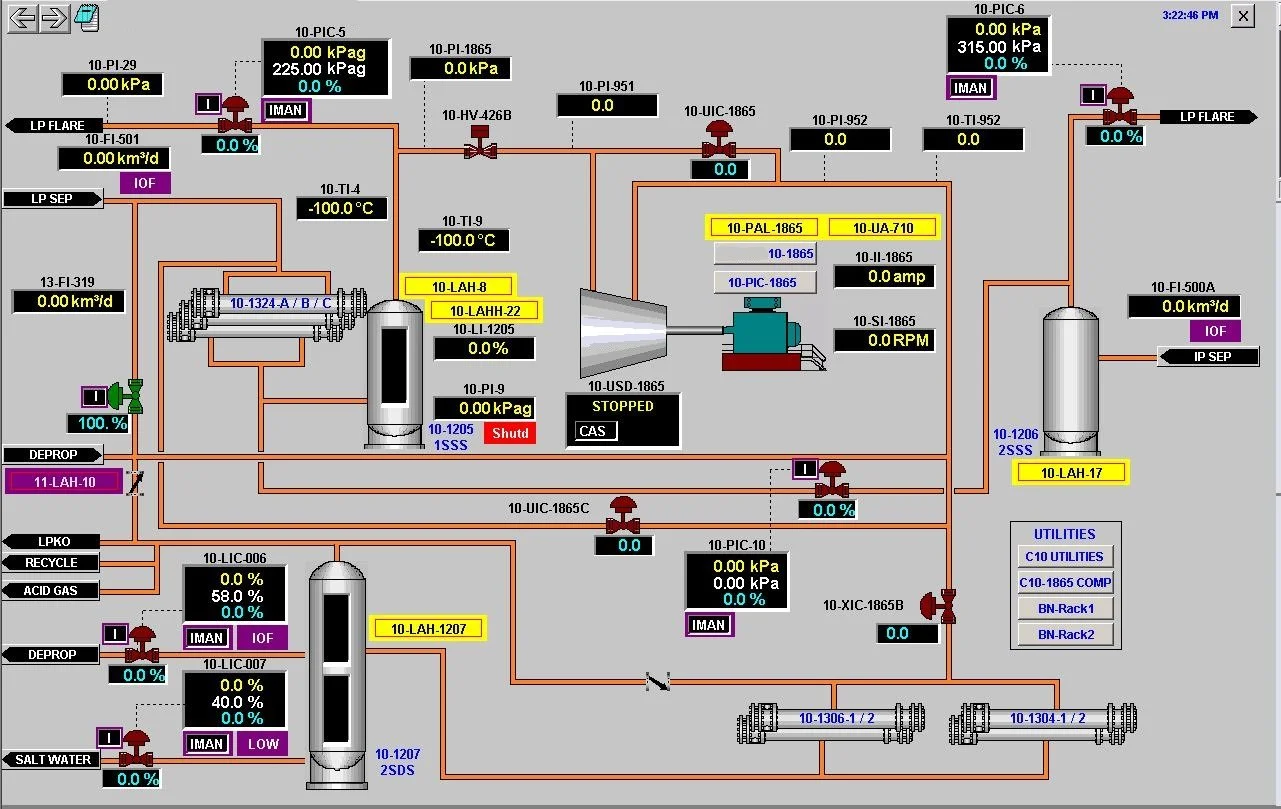

We rely on close collaboration with your team to establish Integrity Operating Windows (IOWs), based on design parameters, OEM guidelines, and industry standards. We then integrate IOWs into your Distributed Control System (DCS) to provide real-time monitoring and annunciation. This proactive approach to integrity management allows for immediate detection and response when IOWs thresholds are exceeded, preventing potential damage before it escalates.

-

In the event that an IOW is exceeded, we work with industry experts to conduct a thorough impact assessment to evaluate the potential effects on your equipment. This includes analyzing the extent of exposure beyond safe limits, identifying potential degradation mechanisms, and predicting the impact on the asset’s integrity and remaining life.

-

Based on the impact assessment, we provide recommendations for immediate actions to mitigate potential damage, such as adjusting operational conditions, altering inspection intervals, or conducting targeted inspections. We also advise on long-term strategies to prevent recurrence, ensuring that your assets remain safe and reliable.

-

We document all findings and actions taken, providing a comprehensive report that helps you understand the incident’s implications and supports informed decision-making for future operations.

By working with us to develop you IOW management system, Systems Approach West helps you maintain the integrity of your assets, reduce the risk of unexpected failures, and ensure long-term operational safety.

Corrosion Circuit Development

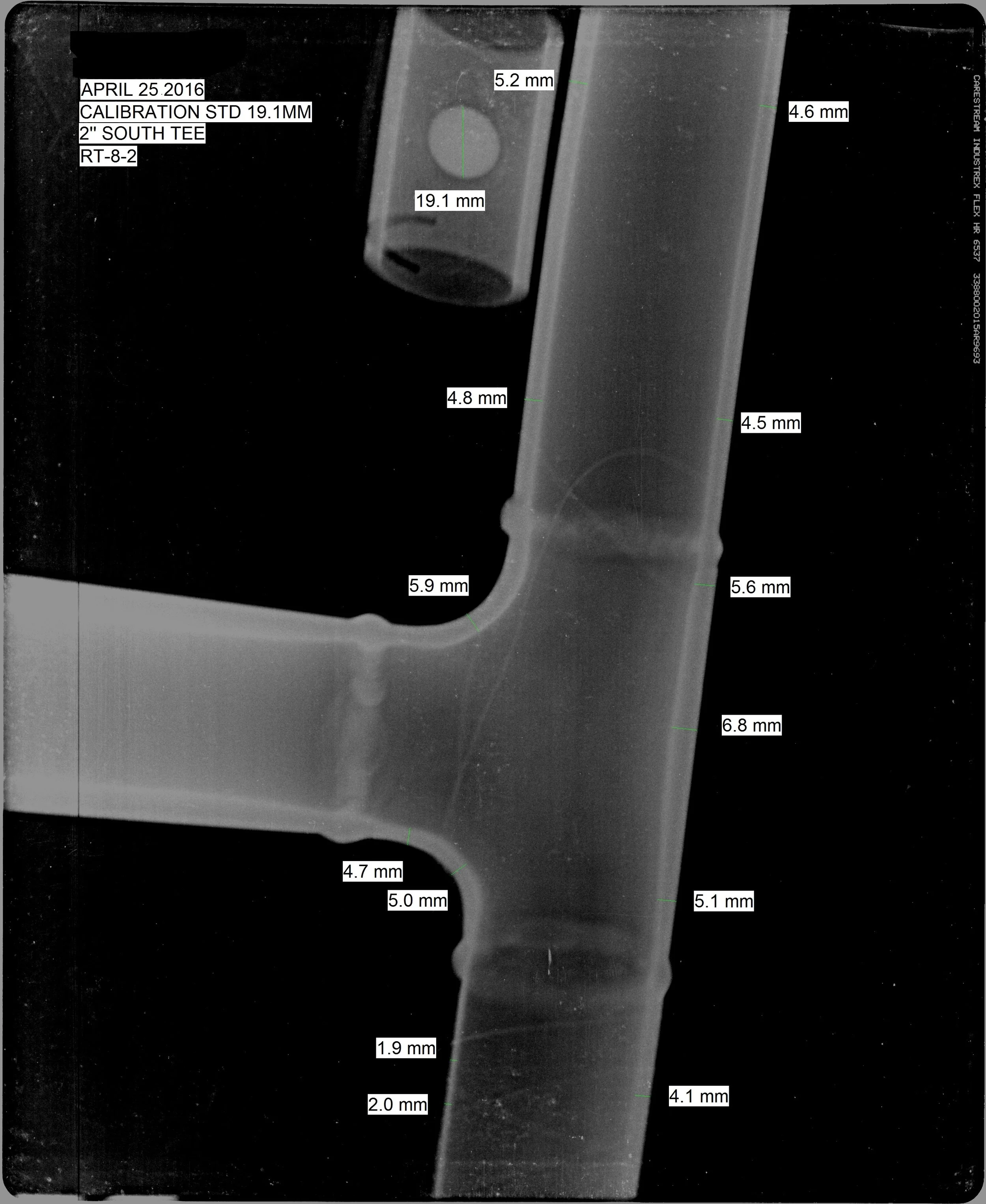

We understand that corrosion is one of the most insidious threats to asset integrity. That's why we take a proactive approach by developing tailored corrosion circuits that pinpoint where your assets are most vulnerable. Our process begins with accurate P&IDs to map out potential risk areas, ensuring a thorough understanding of your system's layout and material interactions.

Expand each consideration below for more information.

-

We meticulously develop corrosion circuits that are specific to your operations, identifying critical areas that require monitoring. This tailored approach ensures that nothing is overlooked, and that your assets are monitored and appropriately inspected for corrosion-related degradation.

-

After establishing these circuits, we work with the best in the industry - experts from Acuren Engineering, FP Innovations, and other leading firms - to identify degradation modes and mechanisms, and perform detailed analysis. These specialists apply advanced techniques to detect and analyze corrosion mechanisms, providing insights that are critical to maintaining asset integrity.

-

We assist in integrating the findings into your existing systems, setting up Distributed Control System (DCS) recommendations for real-time reporting and tracking. This ensures that you have continuous oversight of operating conditions that can adversely affect corrosion rates and can make informed decisions to prevent potential issues before they become critical.

By focusing on the strategic development of corrosion circuits and leveraging top-tier industry expertise, Systems Approach West offers a comprehensive solution that not only identifies risks but actively manages them, extending the life of your assets and ensuring their safe, reliable operation.

Regulatory Compliance Inspections

At Systems Approach West, we recognize the importance of ensuring that your Pressure Piping, Power Piping, Vessels, Tanks, and Pressure Protection Systems comply with regulatory standards. Our approach goes beyond meeting minimum requirements - we help you optimize inspection intervals based on actual asset performance and risk.

Expand each consideration below for more information.

-

We establish time-based inspection programs that align with regulatory requirements. This foundational step ensures that all critical components are inspected at the appropriate intervals, maintaining compliance and operational safety.

-

Over time, we evaluate the results of these inspections to identify trends, potential issues, and opportunities for improvement. This continuous monitoring allows us to gain insights into the actual condition and performance of your assets.

-

Special attention is given to Pressure Protection Systems, where ensuring reliability and compliance is critical to preventing overpressure events and ensuring safe operation.

-

Based on the data collected from time-based inspections, we help you transition to a more dynamic risk-based inspection (RBI) program by refining and developing existing corrosion circuits. This approach allows for the adjustment of inspection intervals - either increasing or decreasing them - based on the specific risks associated with each asset. The result is a more efficient inspection process that enhances safety while optimizing resources.

By working with us to develop you IOW management system, Systems Approach West helps you maintain the integrity of your assets, reduce the risk of unexpected failures, and ensure long-term operational safety.

Risk-Based Inspection (RBI) Methodologies

At Systems Approach West, our Risk-Based Inspection (RBI) methodologies are designed to optimize your inspection and maintenance strategies by focusing efforts on the areas that present the highest risk to your operations. This strategic approach enhances safety and ensures that your resources are allocated where they will have the greatest impact.

Expand each consideration below for more information.

-

We conduct detailed risk assessments of your assets, considering factors such as operating conditions, historical performance data, and potential failure consequences. This analysis identifies the components most at risk of failure, enabling targeted inspection and maintenance.

-

We have successfully applied RBI techniques to critical systems, such as Kraft Recovery Boilers, securing insurance provider and regulatory approval for operating campaign extensions in British Columbia. This demonstrates our ability to extend the safe operational life of key assets while meeting stringent safety and regulatory standards.

-

With a thorough risk assessment, we prioritize inspections based on the severity and likelihood of potential failures. Critical areas receive the attention they need, reducing the chance of unexpected downtime or catastrophic failure, while optimizing your annual budget.

-

Our RBI methodologies are continuously refined as new data becomes available from inspections and operational performance. This ensures that your inspection intervals are always aligned with the actual risk, rather than being based on arbitrary schedules.

-

By focusing inspection efforts on high-risk areas, our RBI approach reduces unnecessary inspections and maintenance activities. This not only cuts costs but also frees up resources for other critical operations.

-

Beyond identifying where inspections are needed, we work with you to implement proactive measures that reduce risk before it leads to failures. This might include operational adjustments, material changes, or revised maintenance practices.

Through our RBI methodologies, Systems Approach West ensures that your inspection and maintenance programs are cost-effective and highly effective in minimizing operational risks, enhancing the safety and reliability of your assets.

Alarm Rationalization and Management

At Systems Approach West, we recognize that effective alarm management is crucial for maintaining safety and control in complex operations. Our alarm rationalization services comply with ISA 18.2 standards, and are meticulously designed to streamline your alarm systems, reduce nuisance alarms, and enhance operator response. This effort ultimately leads to a safer and more efficient operational environment.

Expand each consideration below for more information.

-

We begin by thoroughly reviewing Distributed Control System (DCS) inputs, analyzing the causes, consequences, corrective actions, and required response times (time to respond – TTR) for each alarm. This ensures that every alarm is justified and aligned with your operational safety standards.

-

Utilizing your corporate risk matrix, we evaluate and assign priority levels to alarms - categorized in the correct sequence as advisory, warning, critical, or trip. This approach ensures that alarms are prioritized based on their potential impact on safety and operations, focusing attention where it is most needed.

-

The outcome of our alarm rationalization process is the creation of a detailed alarm management database. This database consolidates cause, consequence, and corrective actions (when feasible based on Time to Respond), providing a comprehensive resource for ongoing management and future reference.

-

Based on the data collected from time-based inspections, we help you transition to a more dynamic risk-based inspection (RBI) program by refining and developing existing corrosion circuits. This approach allows for the adjustment of inspection intervals - either increasing or decreasing them - based on the specific risks associated with each asset. The result is a more efficient inspection process that enhances safety while optimizing resources.

-

The master alarm database we develop is not just a static tool - it is to be managed according to your existing management of change (MOC) program and serves as a valuable input for first-time Process Hazard Analyses (PHAs) or PHA revalidation exercises. By incorporating detailed alarm data into PHAs, we help ensure that safety analyses are comprehensive and that corrective actions are thoroughly evaluated.

-

By reducing unnecessary alarms and focusing on critical alerts, our rationalization process helps create a safer, more controlled environment. Operators are better equipped to respond to genuine issues, improving overall system reliability and safety.

Through our thorough approach to alarm rationalization, Systems Approach West ensures that your alarm management system is optimized, your operators are well-prepared and able to focus their attention where needed, and your operations remain safe and compliant.

Continuous Improvement

We believe that continuous improvement is essential for maintaining the safety, reliability, and efficiency of your assets throughout their lifecycle. Our comprehensive services are designed to ensure that your asset management strategies evolve with changing conditions and requirements, keeping your operations at peak performance.

Expand each consideration below for more information.

-

We begin by conducting a detailed analysis of your assets to determine their remaining useful life. This assessment considers operating history, maintenance records, environmental conditions, and performance metrics. With this information, we provide accurate estimates of how much longer your assets can operate safely and efficiently.

-

Following the life assessment, we assist you in making informed decisions about whether to extend the life of your assets or plan for their replacement. This process includes a risk assessment that weighs the costs and benefits of life extension versus replacement, ensuring that you choose the most cost-effective and safe option.

-

For assets with remaining potential, we develop tailored life extension strategies to address known damage and degradation mechanisms. These strategies may include material upgrades, component replacements, or enhanced maintenance programs designed to extend operational life and improve performance.

-

All life extension strategies are developed in compliance with relevant industry standards and regulations. We work closely with regulatory bodies to ensure that any modifications or continued operations meet safety requirements and receive the necessary approvals.

-

In cases where replacement is the best option, we assist in planning and executing a seamless transition. This includes selecting new equipment that meets current performance and safety standards, managing the decommissioning of old assets, and overseeing the installation and commissioning of replacements.

-

Our goal is to ensure that your operations continue smoothly, whether through life extension or asset replacement. We provide ongoing support to ensure the effectiveness of the strategies we implement, helping you avoid unexpected downtime and maintain operational continuity.

-

As part of our commitment to continuous improvement, we conduct regular audits of your SYSTEM to verify adherence to established protocols and assess functionality. We also incorporate updates based on the latest regulatory, insurance, and industry changes, ensuring that your asset management strategies remain relevant and effective over time.

By partnering with Systems Approach West for end-of-life planning and life extension, you gain access to expert analysis and tailored strategies that maximize the value of your assets while prioritizing safety and efficiency.

Why Choose SYSTEM?

Our SYSTEM strategy offers a unique, proactive, safety-by-design approach to asset management that perfectly aligns with your operational goals. At Systems Approach West, we bring extensive professional qualifications and a deep commitment to excellence in every project we undertake.

Our team is led by highly qualified Professional Engineers (P.Eng.), each with years of industry experience and a track record of successful project execution across various sectors, including oil and gas, pulp and paper, power generation, transportation, and mining. Our P.Eng. qualifications ensure that every aspect of your asset management strategy is developed, reviewed, and endorsed by professionals who meet the highest standards of technical expertise and regulatory compliance.

In addition to our internal expertise, Systems Approach West has a close alignment with LupaTech Ltd., a leader in Process Safety Management (PSM), Oil & Gas troubleshooting, and specialized training. This partnership allows us to integrate advanced PSM techniques and methodologies into our asset management services, providing you with a comprehensive approach that covers not only the mechanical integrity of your assets but also the operational safety and regulatory compliance needed for long-term success.

SYSTEM is more than just a management strategy; it's a collaborative approach that brings together the best in engineering and safety practices. By partnering with us, you gain access to a tailored suite of services designed to enhance the safety, reliability, and efficiency of your assets throughout their lifecycle. Our proactive approach ensures that potential risks are identified and mitigated early, allowing you to focus on achieving operational excellence and long-term success.

Contact Systems Approach West today to discover how SYSTEM can transform your asset management strategy, ensuring your assets are managed with the highest standards of care and expertise.